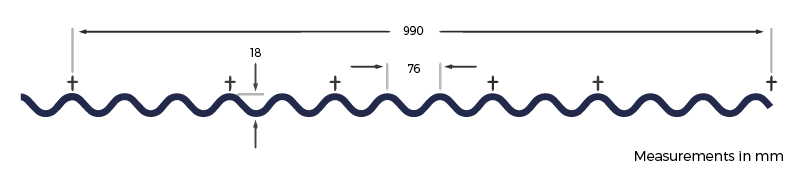

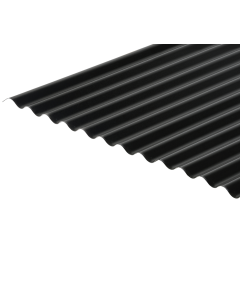

Corrugated roofing sheets are one of the more traditional profiles from our range of metal roofing sheets. Made from high-quality galvanised steel, they feature 13 round corrugations across their width - which improves their structural integrity and provides an authentic waved appearance.

13/3 corrugated profile sheets have been popular among agricultural building projects and barns for many years thanks to their long-lasting, durable structure. Now, they are seeing an increase in popularity when used as a metal wall cladding material on more contemporary domestic and commercial building project styles, especially in a black finish.

Corrugated roofing sheets are a cost-effective roofing option, and their lightweight yet robust profile makes them quick and easy to install.

Sheets are produced in both 0.7mm and 0.5mm thicknesses depending on their end use. If being used for wall cladding, we recommend 0.5mm thick sheets as they do not need to support any load-bearing weight as a roof sheet would.

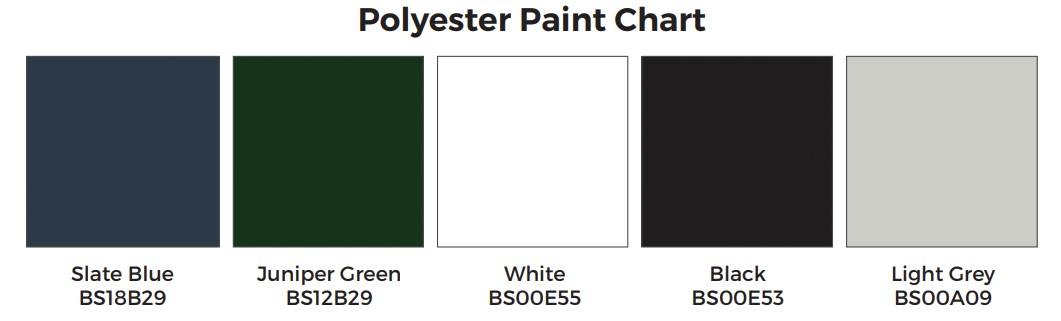

Sheets are available in plain galvanised finishes as well as a range of colours and coatings to suit your project requirements.