Dripstop is a proven, economical way of stopping the underside of a metal roof dripping with condensation on uninsulated panels, by trapping and releasing water droplets back into the air.

Dripstop membrane turns steel sheeting into anti-condensation roof sheets and is designed to reduce dripping, or running condensate, by creating a vapour barrier on metal roofing panels in buildings with moderate to high levels of humidity.

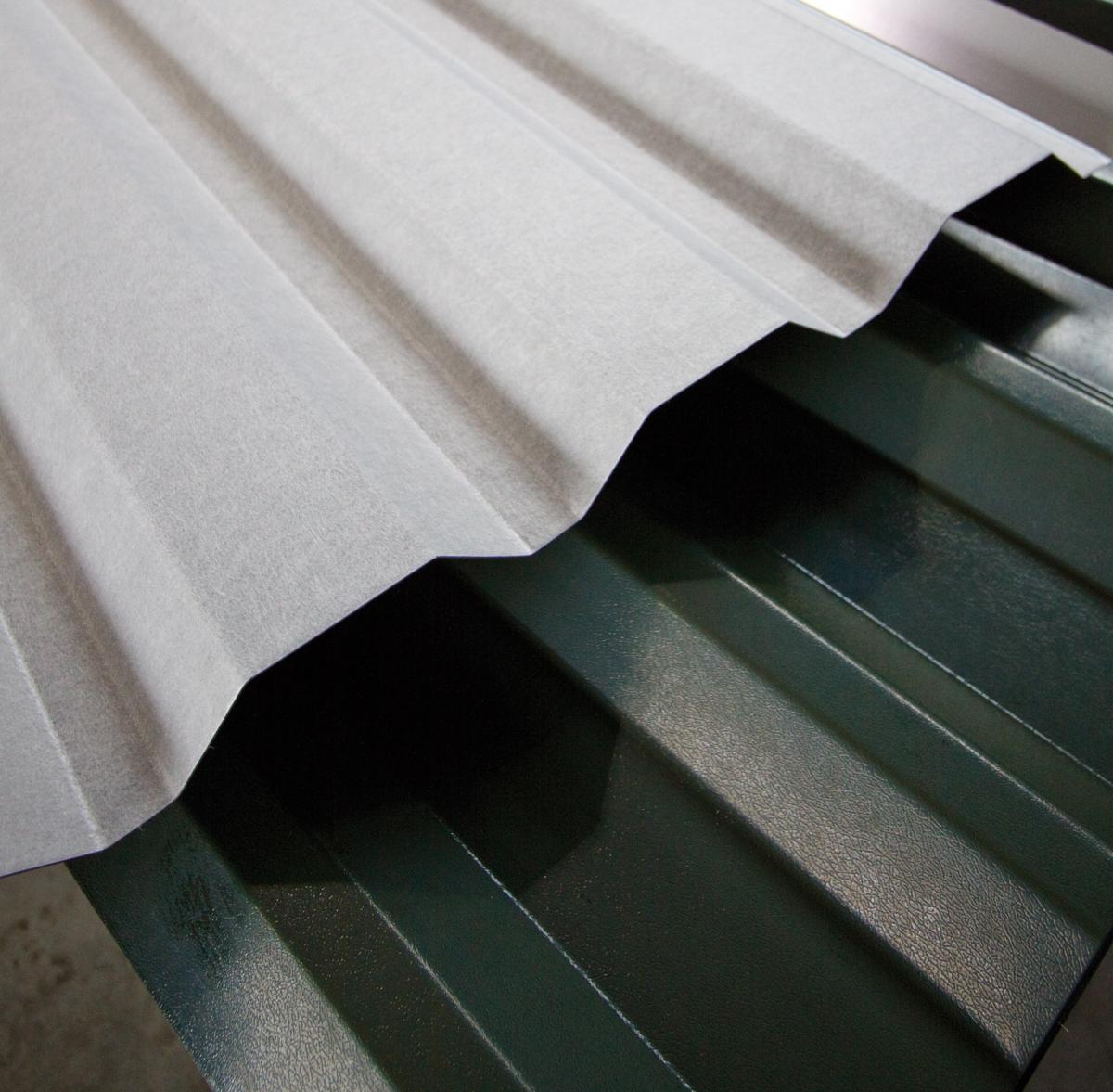

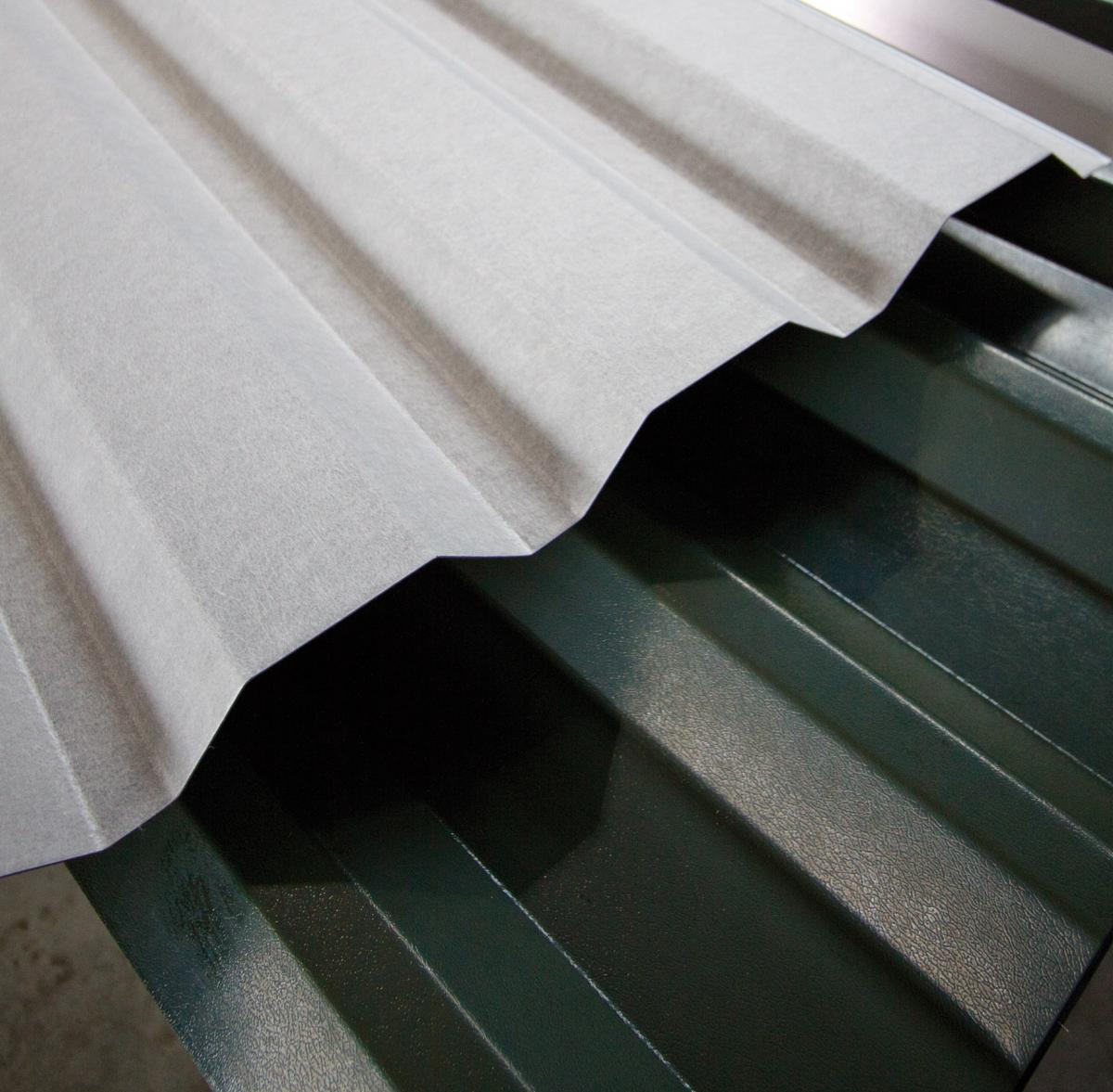

Dripstop anti-condensation felt membrane can be applied to the reverse of Cladco Steel Roofing Sheets, to 34/1000 Box Profile, 32/1000 Box Profile, 13/3 Corrugated and 41/1000 Tile Form panels.

How does Dripstop work?

Dripstop creates a medium for trapping moisture in specially designed pockets formed in the felt membrane.

As moisture condenses in high temperature and humidity conditions, Dripstop controls how cyclical condensate forms onto the underside of steel roofing. It does not prevent condensation from forming and, when working correctly, feels damp to the touch.

To help Dripstop work effectively, it is recommended to have a pitched roof of 10 degrees or more. Any lower than this and the shallow angle will cause the water droplets to drip down off the sheet without effectively evaporating back into the environment.

For Dripstop to work correctly, the building must be adequately ventilated with enough airflow for condensation to dry out between each cycle. Without adequate airflow, condensation is unable to be released back into the air and will remain trapped in the tiny pockets of the felt membrane. This can create a build-up of moisture and will eventually drip down from the sheets onto the contents of the building causing potential water damage.

When does condensation occur?

Condensation can occur when warm air inside a building comes into contact with a cold surface such as a metal panel. This can commonly occur on the underside of an uninsulated metal roof panel during the winter, where warm air during the day cools at night and moisture forms. It can also occur on clear nights when the temperature of the metal surface of a roof is lowered due to night sky radiation.

When the temperature rises above normal humidity and reaches dew point, condensation occurs on surfaces which are colder. This is where the water droplets cool down and where Dripstop holds moisture within the membrane's pockets until conditions go back below the dew point. After which, water droplets are released back into the air in the form of normal humidity and the Dripstop surface dries until the cycle begins again.

Condensation which is left can run down the roof and collect on, or within, the fabric of the building where it could cause rust, rot damage and may also drip from the roof panel directly into the building site.

Typical uses of Dripstop anti-condensation membrane

Dripstop membrane is a resistant material that withstands ripping, tearing or deterioration, and is easy to clean when needed.

With this in mind, Dripstop membrane works well when applied to many different building types, including:

- Agricultural buildings

- Industrial warehouses

- Sheds

- Garages

- Carports

- Storage units

- Canopies

Controlling condensation on roofs in the winter

The cold winter months will be when condensation is most likely to occur, as the cold air outside cools down a metal panel more so than in the summer months.

The warm air on the inside of the building rises and cools as it comes into contact with a cold metal roof and goes from a gas form to a liquid state, creating a wet condensate that stays on a smooth, cold surface.

The Dripstop membrane absorbs and holds condensation until it can evaporate whilst insulating the sheeting and preventing drips from the underside of the roof, thus reducing the formation of condensation. To avoid the condensation from dripping off, water droplets are held within the Dripstop membrane until the temperature rises and in the form of normal humidity.

How is Dripstop anti-condensation membrane applied to sheeting?

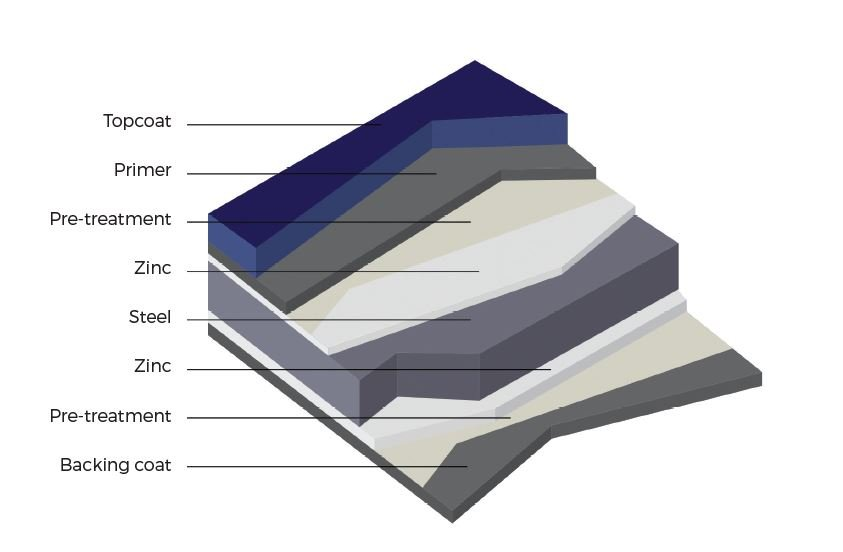

Dripstop membrane is a tried and tested product, applied to roofing panels in the steel roll form process. By applying this during the manufacturing process, the material can be applied on the reverse of the sheeting to prevent ripping, tearing or deterioration.

Dripstop is self-adhesive and provides a long-lasting membrane on the reverse of each roof sheet. This means that when your sheets arrive, they will be ready to use without any tricky installation of the membrane.

How to stop condensation on steel roofing sheets

Dripstop can only be used in buildings with a guaranteed supply of airflow, such as open-sided or fronted buildings, i.e. agricultural barns or industrial units. Without this, conditions will not be right for Dripstop to function effectively.

To prevent moisture from occurring, other forms of standard insulation or traditional solutions can be utilised. Damp air in the form of condensation needs to be managed by adequate insulation under the roof, which includes Dripstop membrane.

Standard insulation can work to stop condensation from occurring. Consider our pre-insulated Roofing Panels, available in a variety of lengths in Goosewing Grey finish.

If you are unsure whether your building has sufficient airflow, please contact our helpful sales team who will be happy to assist you - 01837 659901.